How to Get A Prototype Made In China? 2024 Guidelines

- Sep 6, 2024

- 3 min read

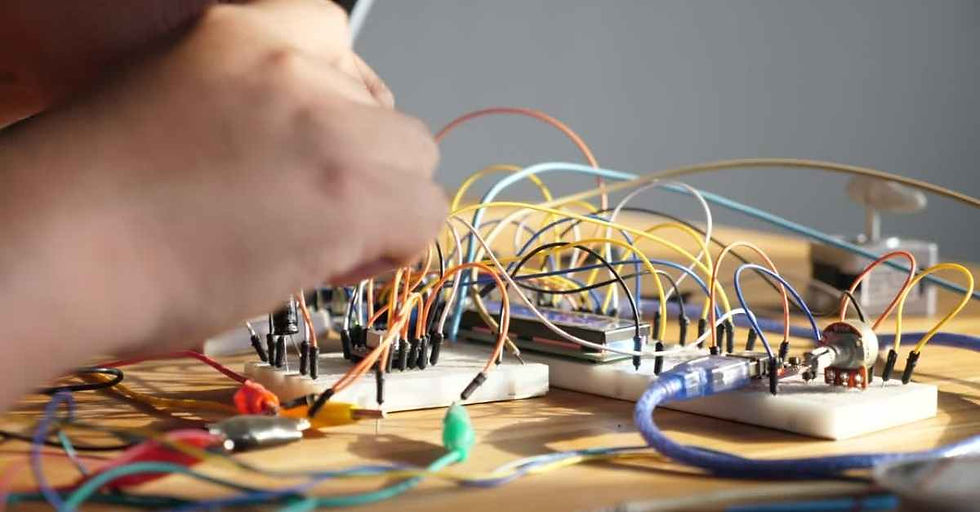

Prototyping is crucial in bringing your product ideas to life, and China has become a top destination for this essential phase. Why? Because of its cost efficiency and advanced manufacturing capabilities. Here’s a streamlined guide to help you navigate the prototyping process in China effectively.

Why Choose China for Prototyping?

Cost Efficiency China offers competitive pricing that can significantly reduce your prototyping costs. This affordability stems from lower labor costs and efficient manufacturing processes, making it an attractive option compared to other regions.

Advanced Manufacturing Capabilities Chinese manufacturers are equipped with cutting-edge technology and expertise across various industries. Whether you’re in electronics, consumer goods, or automotive, China’s manufacturing prowess can support complex and high-quality prototypes.

Key Steps to Getting Your Prototype Made in China

Research and Select the Right Manufacturer Choosing the right manufacturer is critical to the success of your prototyping project. Begin by identifying manufacturers with experience in your specific industry. Look for companies that specialize in the type of prototype you need—whether it's consumer electronics, medical devices, or automotive parts. Utilize platforms like Alibaba, Global Sources, or industry-specific directories to find potential candidates.

Check Credentials: Verify certifications such as ISO 9001, which indicates quality management standards, and any industry-specific certifications relevant to your prototype.

Review Past Work: Examine their portfolio to assess their capabilities. Request case studies or examples of similar projects they have completed.

Request References: Contact previous clients to gain insights into their experience with the manufacturer, focusing on quality, communication, and adherence to deadlines.

Initial Communication and Quoting Effective communication sets the stage for a successful collaboration. When reaching out to manufacturers, provide comprehensive details about your prototype.

Detailed Specifications: Share detailed CAD drawings, material requirements, and functional expectations. The more information you provide, the more accurate the quote will be.

Understand the Quote: Ensure that the quote includes all potential costs, such as tooling, material, labor, and shipping. Be aware of any additional fees for revisions or expedited services.

Negotiate Terms: Discuss payment terms, lead times, and quality assurance practices. Establish clear deadlines and penalties for delays to protect your interests.

Prototype Design and Specifications Clear and precise design specifications are crucial for the successful development of your prototype.

Provide Comprehensive Design Files: Use detailed and accurate design files to minimize misunderstandings. Include specifications on dimensions, tolerances, and material properties.

Feasibility Analysis: Work with the manufacturer to assess the feasibility of your design. They may offer valuable feedback on potential design improvements or material substitutions that can enhance functionality or reduce costs.

Prototype Testing and Validation: Plan for initial testing phases to validate the prototype against your requirements. Ensure that the manufacturer has the capability to conduct necessary tests, such as stress tests or performance evaluations.

Navigating the Prototyping Process

Sample Creation and Testing: Expect to receive sample prototypes. Use this phase to test functionality and make necessary adjustments. Effective testing ensures your final product meets all performance standards.

Revisions and Iterations: Be prepared for revisions. Provide feedback promptly to refine the prototype. This iterative process helps you achieve the final product that meets your expectations.

Quality Control and Assurance

Ensuring High Standards: Maintain quality by implementing strict quality control measures. Regular inspections and testing at different stages of production can help catch issues early.

Managing Risks: Be aware of common risks such as delays or quality discrepancies. Establish clear agreements and maintain open communication to address any issues swiftly.

Legal and Logistical Considerations

Intellectual Property Protection: Protect your intellectual property with legal agreements. Non-disclosure agreements (NDAs) and patents can prevent copying your designs.

Shipping and Customs: Understand shipping options and customs procedures. Plan logistics carefully to ensure smooth delivery and avoid unexpected delays.

Outsourcing prototyping to China offers significant advantages, including cost savings and access to high-quality manufacturing. By following these guidelines, you can streamline the prototyping process and avoid common pitfalls. At Esino, our account manager, Zac Marton, is here to guide you through every step, from the initial concept to the final prototype. Contact Zac at z.marton@esinousa.com today to discover how he and our team can ensure your project's success. Ready to get started? Reach out to Esino for expert assistance with your prototyping needs!

Comments